When asked which belts are most prone to causing downtime, the nearly unanimous response is “Radius Belts”. Radius belts are often conveying product long distances, over the top of other conveyors, and even through walls. In other words, they are difficult to reach, should they need repair, and very expensive to replace.

Safari Belting understands that the greatest stress to a radius belt occurs during the turn where the force is greatest on the outside edge of the belt.

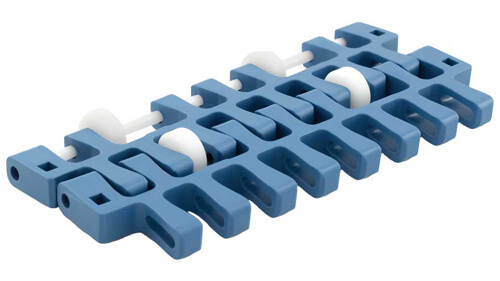

To improve the performance of its radius belts, Safari Belting made some important design improvements:

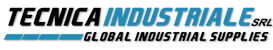

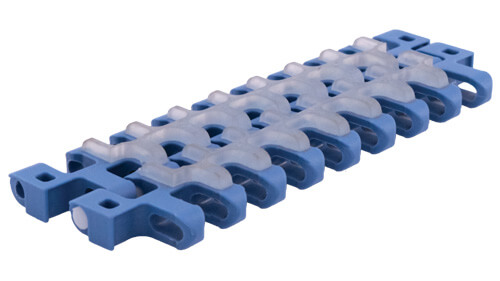

Plastic was added to the “knuckle” areas of the belts, making them much more robust and able to withstand the increased force during turns.

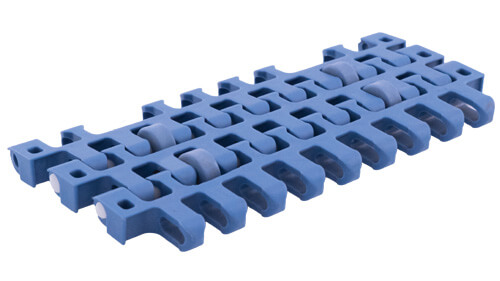

Traditional radius belts utilize a passive rod retention system (rods simply slide into position). Safari Belting utilizes a robust, headed rod in its radius belt designs. Headed rods are actively engaged into the belts which prevents them from “walking” out and snagging on the conveyor. The competitor’s passive rod retention design permits the force through the turns to work the rods out of position, resulting in frequent break-downs.

Edge modules in Safari Belting’s radius belts were reinforced to dramatically reduce breakage of the edge knuckles, another cause of frequent break-downs.