8 | helIcal and bevel helIcal gearmotorS |

A series | |

9 | C series |

10 | S series |

11 | F series |

Worm gearmotorS | |

12 | VF and W series |

Planetary gear unItS | |

13 | 300 series |

helIcal and bevel helIcal gearboxeS | |

14 | HDP series |

15 | HDO series |

16 | TA series |

bevel gearS | |

17 | RAN series |

InduStry-SPecIfIc SolutIonS | |

18 | EP series |

19 | ATEX compliant gear units |

20 | 3/H series |

21 | HDPE series |

PrecISIon Planetary gearboxeS | |

22 | LC series |

23 | LCK series |

24 | MP series |

25 | TR series |

26 | SL series |

27 | KR series |

28 | TQ series |

29 | TQK series |

electrIc motorS | |

30 | BN/M series |

31 | BE/ME series |

32 | BX/MX series |

33 | BS series |

34 | BC series |

ServomotorS | |

35 | BMD series |

36 | BTD series |

37 | BCR series |

frequency Inverter | |

38 | AGILE series |

39 | ACTIVE series |

40 | ACTIVE CUBE series |

41 | ACTIVE CUBE series - Size 8 |

42 | VCB series |

43 | S2U series |

human machIne InterfaceS | |

44 | BMI series |

45 | our qualItIeS |

46 | WorldWIde netWork |

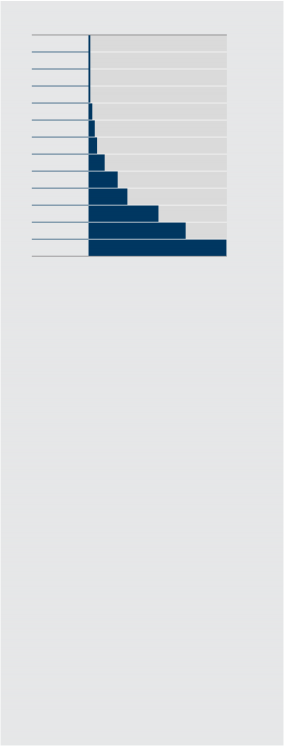

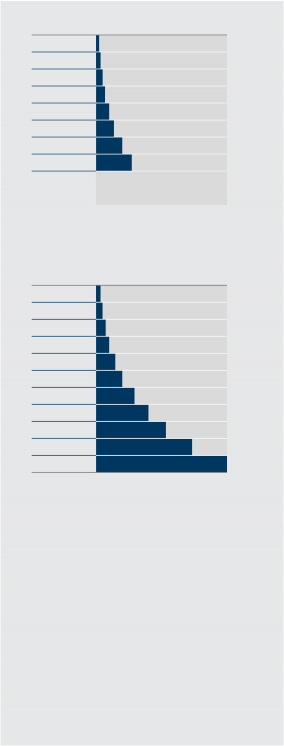

Industrial market segment is covered through the following Product Lines:

![]()

Product offer

![]()

![]()

![]()

![]()

a series

Bonfiglioli Helical-bevel gearmotors

When efficiency and versatility meet each other.

The A series is the first product to prove equally good in regard to efficiency and versatility within a highly competitive context, both performance- and price-wise.

Torque range

100 ... 14000 Nm

1

Mechanical rating (n = 1400 min-1)

Type Torque [Nm]

A 05 | 100 | ||

A 10 | 150 | ||

A 20 | 250 | ||

A 30 | 410 | ||

A 35 | 600 | ||

A 41 | 850 | ||

A 50 | 1500 | ||

A 55 | 2000 | ||

A 60 | 2800 | ||

A 70 | 5000 | ||

A 80 | 8000 | ||

A 90 | 14000 | ||

0.22 ... 150 kW

Gear ratios

5.4 ... 1715

Output

Foot and shaft mount - two bore options per size Keyless shrink disc fitting

Metric or Inch series solid output shaft

Taper bushings matching more shaft diameters Splined hollow shaft to DIN 5480

Input

IEC and NEMA motor adaptors Servomotor adapters

Metric or inch series solid input shaft

Main gear options

Backstop

Reinforced bearings for higher overhung load capacity Reducedbacklash

Taconite seals

Applicable AC motors

Integral motors and brake motors - M series / ME series

IEC-normalized motors and brake motors - BN series / BE series Single and dual speed motors

Main brake features

DC and AC supply

Faster brake engage/disengage through electronically Controlled AC/DC rectifier type SB, NBR, SBR (options)

Main motor options

Thermistors and thermostat sensors Separate supply forced ventilation

Line driver and push-pull incremental encoder

c series

In-line helical gearmotors

When Customers benefit from the know-how developed over the years.

Top torque density, product variety, extremely wide speed choice, great compactness and price effectiveness make the C series the unparalleled line of helical gearmotors and speed reducers.

Type Torque [Nm]

Torque range

45 ... 12000 Nm

1

Mechanical rating (n = 1400 min-1)

C 05 | 45 | ||

C 12 | 100 | ||

C 22 | 200 | ||

C 32 | 300 | ||

C 36 | 450 | ||

C 41 | 600 | ||

C 51 | 1000 | ||

C 61 | 1600 | ||

C 70 | 2300 | ||

C 80 | 4000 | ||

C 90 | 7200 | ||

C 100 | 12000 | ||

0.08 ... 213 kW

Gear ratios

2.6 ... 1481

Output

Foot and flange mount

Metric or inch series solid output shaft

Input

IEC and NEMA motor adaptors Servomotor adapters

Metric or inch series solid input shaft

Applicable AC motors

Integral motors and brake motors - M series / ME series

IEC-normalized motors and brake motors - BN series / BE series Single and dual speed motors

Main brake features

DC and AC supply

Faster brake engage/disengage through electronically Controlled AC/DC rectifier type SB, NBR, SBR (options)

Main motor options

Thermistors and thermostat sensors Separate supply forced ventilation

Line driver and push-pull incremental encoder

S series

Bonfiglioli Single reduction helical gearmotors

Simplicity above all.

Simple and yet powerful is the S series, developed for the pump industry as well as the fan and blower application.

Foot and flange mounted, with shaft dimensions to the UNEL - MEC standard.

Torque range

21 ... 200 Nm

1

Mechanical rating (n = 1400 min-1)

Type Torque [Nm]

S 10 | 21 | ||

S 20 | 37 | ||

S 30 | 70 | ||

S 40 | 125 | ||

S 50 | 200 | ||

0.12 ... 11.6 kW

Gear ratios

1.4 ... 13.1

Output

Foot and flange mount

Input

IEC-normalized motor adaptors Solid input shaft

Applicable AC motors

Integral motors and brake motors - M series / ME series

IEC-normalized motors and brake motors - BN series / BE series Single and dual speed motors

Main brake features

DC and AC supply

Faster brake engage/disengage through electronically Controlled AC/DC rectifier type SB, NBR, SBR (options)

Main motor options

Thermistors and thermostat sensors Separate supply forced ventilation

Line driver and push-pull incremental encoder

f series

Shaft mounted gearmotors

![]()

Type Torque [Nm]

Ruggedness and effectiveness to the state-of-the-art.

No better, easier and neater installation than with a shaft mounted unit of the F series. Lightweight and performing, an F unit is the dependable drive for all the material handling applications.

Torque range

140 ... 14000 Nm

1

Mechanical rating (n = 1400 min-1)

F 10 | 140 | ||

F 20 | 250 | ||

F 25 | 400 | ||

F 31 | 600 | ||

F 41 | 1100 | ||

F 51 | 1800 | ||

F 60 | 2900 | ||

F 70 | 5000 | ||

F 80 | 8000 | ||

F 90 | 14000 | ||

0.17 ... 125 kW

Gear ratios

6.4 ... 2099

Output

Keyed hollow shaft - two bore options per size Keyless shrink disc fitting

Plug-in solid output shaft as an option

Input

IEC and NEMA motor adaptors Servomotor adapters

Metric or inch series solid input shaft

Applicable AC motors

Integral motors and brake motors - M series / ME series

IEC-normalized motors and brake motors - BN series / BE series Single and dual speed motors

Main brake features

DC and AC supply

Faster brake engage/disengage through electronically Controlled AC/DC rectifier type SB, NBR, SBR (options)

Main motor options

Thermistors and thermostat sensors Separate supply forced ventilation

Line driver and push-pull incremental encoder

vf W series

Bonfiglioli Worm gearmotors

A smart design enhanced by latest materials technology and advanced manufacturing.

Wormgears of the VF and W series are milestones for the industry worldwide.

They succeeded in combining uncompromising quality with state-of-the-art technology and renown price effectiveness.

Absolute flexibility is achieved by the wide choice of mounting options, shaft configurations and motor interfaces, all offered as standard. The helical-worm and the double-worm versions, with or without the torque limiter, also enhance a highly versatile drive system.

Torque range

13 ... 7100 Nm

Type Torque [Nm]

1

Mechanical rating (n = 1400 min-1)

0.04 ... 75 kW

Gear ratios

7 ... 10000

Output

Keyed hollow shaft

Plug-in solid output shaft Torque limiter as an option

Input

IEC-normalized motor adaptors Solid input shaft

Applicable AC motors

Integral motors and brake motors - M series / ME series

IEC-normalized motors and brake motors - BN series / BE series Single and dual speed motors

Main brake features

DC and AC supply

Faster brake engage/disengage through electronically Controlled AC/DC rectifier type SB, NBR, SBR (options)

Main motor options

Thermistors and thermostat sensors Separate supply forced ventilation

Line driver and push-pull incremental encoder

VF 27

VF 30

VF 44

VF 49

W 63

W 75

W 86

W 110

VF 130

VF 150

VF 185

VF 210

VF 250

13

24

55

88

190

320

440

830

1500

2000

3600

5000

7100

300 series

Planetary gearmotors

A powerful solution to heavy duty drive needs.

Compact, and yet extremely powerful, are the units of the 300 series. Their planetary drive train makes them the ideal choice for all the severe duty applications where shock loadings and impacts are more the rule than the exception. The product configuration is highly versatile, due to the largely modular options of mounting, gear layout, output shafts and motor interfaces. All features are available for each of the 20 closely spaced frame sizes, spanning over the 1250 - 1286700 Nm torque range. Finding the perfect match to any drive problem is therefore more than a wish, it is something users can safely rely on - always.

Type Torque [Nm]

Torque range

1250 ... 1286000 Nm

1

Mechanical rating (n = 1500 min-1)

300 | 1250 | ||

301 | 2460 | ||

303 | 2970 | ||

304 | 3960 | ||

305 | 5800 | ||

306 | 10840 | ||

307 | 15680 | ||

309 | 23240 | ||

310 | 34120 | ||

311 | 48330 | ||

313 | 57970 | ||

314 | 84000 | ||

315 | 105000 | ||

316 | 138820 | ||

317 | 208110 | ||

318 | 280580 | ||

319 | 476410 | ||

321 | 655740 | ||

323 | 890310 | ||

325 | 1286000 | ||

up to 450 kW

Gear ratios

3.4 ... 5234

Gear unit versions

In line

Right angle (with Gleason bevel gear set)

Output

Foot and flange mounted

Output shaft: keyed solid, splined, splined hollow, hollow shaft with shrink disc

Input

IEC and NEMA motor adaptors

Solid input shaft with or without fan cooling - inch or metric dims.

Applicable AC motors

Integral motors and brake motors - M series / ME series

IEC-normalized motors and brake motors - BN series / BE series Single and dual speed motors

Main brake features

DC and AC supply

Faster brake reaction through electronically controlled rectifier

Main motor options

Thermistors and thermostat sensors Independent forced cooling

Line driver and push-pull incremental encoder

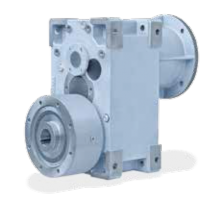

hdP series

Bonfiglioli Parallel shaft gear units

The new benchmark in the parallel shaft category.

High torque ratings, gear ratios in close progression, numerous mounting options, together with compact dimensions will facilitate the engineering of any application.

The housing, made from nodular cast iron ensures robustness even in the harshest environment. State of the art precision ground gears help to produce an extremely quiet and vibration-free product.

Torque range

5000 ... 210000 Nm

Gear ratios

7.1 ... 500

Mounting

Foot, flange, shaft mounting

Input

Solid shaft, motor adapter

Output

Solid (single and double extension), keyed hollow, shrink disc

Options

Fan cooling, cooling coil, heaters Independent cooling systems Backstop

Forced lubrication

Temperature and oil level sensors Drywell

Taconite seals

HDP 60 | 5190 | ||

HDP 70 | 7080 | ||

HDP 80 | 12600 | ||

HDP 90 | 17900 | ||

HDP 100 | 28200 | ||

HDP 110 | 31700 | ||

HDP 120 | 41000 | ||

HDP 125 | 49000 | ||

HDP 130 | 69500 | ||

HDP 140 | 87000 | ||

HDP 150 | 117000 | ||

HDP 160 | 147000 | ||

HDP 170 | 190000 | ||

HDP 180 | 210000 | ||

Type Torque [Nm]

hdo series

Bevel helical gear units

The heavy-duty product that matches performance and versatility with compactness.

The new bevel helical series from Bonfiglioli optimises superior performance with compact dimensions and flexibility. The many standard options that can be selected from the catalogue facilitate customization to meet specific application requirements.

The gear case is nodular cast iron to guarantee rigidity in all circumstances while the gears, using latest profile ground finishing techniques, ensure quiet and vibration-free operation even in the harshest conditions.

HDO 100 | 28200 | ||

HDO 110 | 31700 | ||

HDO 120 | 41000 | ||

HDO 125 | 49000 | ||

HDO 130 | 69500 | ||

HDO 140 | 87000 | ||

HDO 150 | 117000 | ||

HDO 160 | 147000 | ||

HDO 170 | 190000 | ||

HDO 180 | 210000 | ||

Type Torque [Nm]

Torque range

28200 ... 210000 Nm

Gear ratios

5.6 ... 400

Mounting

Foot, flange, shaft mounting

Input

Solid shaft, lantern housing c/w flexible coupling double input shaft (pony drive)

Output

Solid (single and double extension), keyed hollow, shrink disc

Options

Fan cooling, cooling coil, heaters Independent cooling systems Backstop

Forced lubrication

Temperature and oil level sensors Drywell

Taconite seals

ta series

Bonfiglioli Shaft mounted speed reducers

![]()

The sturdy and weather-resistant product for the material handling industry.

The TA series is long established, and well respected in industry, especially in quarry and mine applications where absolute reliability and low maintenance are key factors.

Also appreciated is the backstop option that prevents backdriving on inclined conveyors or elevators.

1

Torque range (n = 900 min-1)

150 ... 16000 Nm

1

Mechanical rating (n = 900 min-1)

Type Torque [Nm]

TA 30 | 150 | ||

TA 35 | 400 | ||

TA 40 | 900 | ||

TA 45 | 1350 | ||

TA 50 | 2100 | ||

TA 60 | 3500 | ||

TA 70 | 4900 | ||

TA 80 | 6600 | ||

TA 100 | 10500 | ||

TA 125 | 16000 | ||

1.1 ... 156 kW

Gear ratios

5.0 ... 31.5

Output

Keyed hollow shaft

Up to three bore options per frame size

Gearcase

Sturdy cast iron housing suitable for outdoor installation

Backstop

Available on all frame sizes - externally accessible

ran series

Bevel gears

The handy drive when it comes to angled transmissions.

The units of the RAN series are designed to fit the purposes of transmissions laid out in right angle setting. Easy to fit and largely maintenance-free, RAN units offer multiple shaft arrangements and a choice of several exact gear ratios, beside the 1:1, that come in handy when designing synchronized drive systems. Also available in the version for screw jack duty.

Type Torque [Nm]

Torque range

3 ... 3000 Nm

1

Mechanical rating (n = 1400 min-1)

RAN 1 | 1350 | |

RAN 2 | 3000 | |

RAN 2R | 3000 | |

0.15 ... 91 kW

Gear ratios

RAN 8 | 3 | ||

RAN 15 | 8 | ||

RAN 18 | 15 | ||

RAN 20 | 28 | ||

RAN 24 | 80 | ||

RAN 25 | 39 | ||

RAN 28 | 150 | ||

RAN 38 | 300 | ||

RAN 48 | 600 | ||

1.0 ... 7.4

Shaft arrangement

Single and double shaft projection

Input

Solid input shaft

RAN 1 / RAN 2 / RAN 2R

194000

Input

Solid - single and double projection Output shaft

Keyed hollow

Gear ratios

i = 3

Rated thrust capacity

RAN 1 50000 N

RAN 2 80000 N RAN 2R 150000 N

W vf_eP series

Bonfiglioli Gearmotors for hostile environments

When multi-purpose products become specific and meet industry requirements. Wormgears and motors are also available in the enhanced protection “EP” configuration, featuring food grade specifications and extra corrosion protection, ensuring risk free operation in hygienic environments, and facilitate effective sanitising. In addition to food processing applications, the EP configuration will also suit the requirements of the chemical and pharmaceutical industry, as well as marine on-board and quayside installations.

Applications

Food processing, chemical and pharmaceutical industry Marine on-board and quayside installations

Corrosive and/or highly hygienic environments

Availability on

Gears: VF 44, VF 49, W 63, W 75, W 86 Motors: BN 63 … BN 112 / M1SD … M3LC

Standard features

Stainless steel hollow shaft

Stainless steel mounting hardware and tag Oil seals loaded with stainless steel spring Sealed gearcase (unvented)

Unused tapped holes closed with button plugs Four draining holes on motor DE and NDE shield Motor protection IP 56

Options

Epoxy primer+epoxy top coating FDA approved Washdown duty oil seals

Food grade lubricant, class H1

Configurations

Foot, flange and shaft mount

Accessories

Plug-in solid output shaft from stainless steel Safety cover for the hollow output shaft Torque arm

VF_EP 27 | 13 | ||

VF_EP 30 | 24 | ||

VF_EP 44 | 55 | ||

VF_EP 49 | 88 | ||

W_EP 63 | 190 | ||

W_EP 75 | 320 | ||

W_EP 86 | 440 | ||

W_EP 110 | 830 | ||

VF_EP 130 | 1500 | ||

VF_EP 150 | 2000 | ||

VF_EP 185 | 3600 | ||

VF_EP 210 | 5000 | ||

VF_EP 250 | 7100 | ||

Type Torque [Nm]

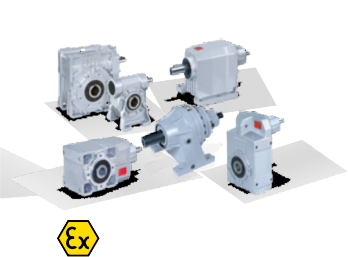

atex series

Gearboxes for explosive environments

Ideal for potentially explosive conditions.

ATEX-compliant gear units in categories 2G and 2D are available, according to the classification set forth by the European Directive 94/9/CE, applying to areas with presence of potentially explosive atmosphere.

C 12 | 100 | ||

C 22 | 200 | ||

C 32 | 300 | ||

C 36 | 450 | ||

C 41 | 600 | ||

C 51 | 1000 | ||

C 61 | 1600 | ||

Type Torque [Nm]

![]()

Coaxials series C

Torque range: 100 ... 1600 Nm

Bevel helicals series A

Torque range: 150 ... 2800 Nm

Shaft mounts series F

Torque range: 140 ... 2900 Nm

Worm gears series VF and W

A 10 | 150 | ||

A 20 | 250 | ||

A 30 | 410 | ||

A 35 | 600 | ||

A 41 | 850 | ||

A 50 | 1500 | ||

A 55 | 2000 | ||

A 60 | 2800 | ||

Torque range: 24 ... 830 Nm

Planetaries series 300

Torque range: 1250 ... 1286000 Nm

F 10 | 140 | ||

F 20 | 250 | ||

F 25 | 400 | ||

F 31 | 600 | ||

F 41 | 1100 | ||

F 51 | 1800 | ||

F 60 | 2900 | ||

VF 30 | 24 | ||

VF 44 | 55 | ||

VF 49 | 88 | ||

W 63 | 190 | ||

W 75 | 320 | ||

W 86 | 440 | ||

W 110 | 830 | ||

300 | 1250 | ||

301 | 2460 | ||

303 | 2970 | ||

304 | 3960 | ||

305 | 5800 | ||

306 | 10840 | ||

307 | 15680 | ||

309 | 23240 | ||

310 | 34120 | ||

311 | 48330 | ||

313 | 57970 | ||

314 | 84000 | ||

315 | 105000 | ||

316 | 138820 | ||

317 | 208110 | ||

318 | 280580 | ||

319 | 476410 | ||

321 | 655740 | ||

323 | 890310 | ||

325 | 1286000 | ||

3/h series

Bonfiglioli Combined gearboxes

Performance and technology of the planetary gearboxes with the robustness and reliability of bevel helical gearboxes.

Bonfiglioli’s 3/H gearboxes combine the high technology, performance and efficiency of planetary gearboxes with the robustness, quality and reliability of bevel helical gearboxes. These planetary/bevel helical combination gear boxes deliver the high transmissible torque of Bonfiglioli planetary 300 Series along with the excellent power transmission characteristics of bevel helical HDO Series and are ideal for applications that demand high power density along with medium-low output speeds.

Torque range

98000 ... 1200000 Nm

Gear ratios

1:100 ... 1:1000

Rated power

up to 980 kW

Reference torque

up to 1200 kNm

Output versions

Solid cylindrical shaft Solid shaft with keyway

Solid shaft with supporting feet

Solid shaft with keyway and supporting feet Hollow shaft with shrink disc

Hhollow shaft with keyway

Input versions

Single sided cylindrical shaft

Flange with motor coupling bell and intermediary elastic joint between the cylindrical shafts of the motor and gearbox.

Mounting position Horizontal input shaft Vertical input shaft

Shaft arrangement

Depending on the needs of the application, 3/HDO combination gearboxes can be supplied with output shafts on the left or right side.

Options & Accessories

Auxiliary thermal devices

Forced lubrication

Backstop device

3/HDO 15 | 98000 | ||

3/HDO 16 | 130000 | ||

3/HDO 17 | 175000 | ||

3/HDO 18 | 260000 | ||

3/HDO 19 | 440000 | ||

3/HDO 21 | 615000 | ||

3/HDO 23 | 830000 | ||

3/HDO 25 | 1200000 | ||

Type Torque [Nm]

Type Torque [Nm]

hdPe series

Extruder gearbox

![]()

The new benchmark in the parallel shaft category.

The HDPE Extruder gearbox series is the configuration specifically developed for single- screw extruder drive generated from the renown heavy duty series HDP, with which it shares most of the component parts and gearing.

Mounted forward to the sturdy nodular cast iron case, and housed into a robust extruder support, HDPE units feature a heavy duty spherical roller thrust bearing of series 294…E, exclusively sourced from primary brands.

Torque range

4650 ... 75000 Nm

Gear Ratios

HDP 60 | 4650 | ||

HDP 70 | 6350 | ||

HDP 80 | 11500 | ||

HDP 90 | 16550 | ||

HDP 100 | 24000 | ||

HDP 110 | 28700 | ||

HDP 120 | 35300 | ||

HDP 130 | 59300 | ||

HDP 140 | 75000 | ||

N

7,1 i

125.0 with progression = 1,12

Mounting

Foot

Input

solid shaft, direct motor mounting, lantern housing with flexible coupling

Output shaft

Thrust bearing of various dimension and capacity and hollow shafts of various shapes and dimensions

Standard shaft is keyed hollow to UNI 6604

Mounting dimensions to customer specifications can be provided

Options

Cooling coil, autonomous cooling units, temperature and oil level sensors

lc series

Bonfiglioli Low backlash planetary gearboxes

![]()

LC planetary precision gearboxes represent a flexible solution, and economic alternative together with an optimal performance and reliability.

Improved performance as the key to downsizing.

Enhanced performance of our LC precision gearboxes (“P” option) may open up important downsizing options as an option in many applications where previously was impossible to ensure a higher transmissible output torque.

As an additional benefit downsizing lead to an improvement of energy efficiency by selecting a more compact gearbox with higher torque density and reducing significantly the accelerating mass.

Transmissible torque is now improved up to 40%!!!

Torque range

12 ... 450 Nm

Maximum acceleration torque

20 ... 700 Nm

Transmission ratios

3 ... 100

Output configuration

Flange mounting

Input configuration

Wide range of coupling configurations to suit most common servomotors

Maintenance

Lubricated for life

Product Line Up

High Torque Density Option “P” available to extend the product performance Optimal Acceleration and Nominal Torques

Optimal Radial and Axial Load Capacities Designed for Cyclic and Continuous Duty Optimal Torsional Stiffness

Geometrical Backlash less than 6 arcmin Universal design allow any Mounting Orientation

Type Rated torque [Nm]

LC 050 | 12 | ||

LC 070 | 25 | ||

LC 070P | 30 | ||

LC 090 | 43 | ||

LC 090P | 65 | ||

LC 120 | 110 | ||

LC 120P | 155 | ||

LC 155 | 300 | ||

LC 155P | 450 | ||

LC 050 | 20 | ||

LC 070 | 35 | ||

LC 070P | 55 | ||

LC 090 | 80 | ||

LC 090P | 120 | ||

LC 120 | 190 | ||

LC 120P | 300 | ||

LC 155 | 450 | ||

LC 155P | 700 | ||

Type Acceleration torque [Nm]

Backlash [arcmin] Standard lower than 12 arcmin Reduced lower than 16 arcmin

Type Rated torque [Nm]

LCK 050 | 12 | ||

LCK 070 | 25 | ||

LCK 070P | 30 | ||

LCK 090 | 43 | ||

LCK 090P | 65 | ||

LCK 120 | 110 | ||

LCK 120P | 155 | ||

LCK 155 | 300 | ||

LCK 155P | 450 | ||

LCK 050 | 20 | ||

LCK 070 | 35 | ||

LCK 070P | 55 | ||

LCK 090 | 80 | ||

LCK 090P | 120 | ||

LCK 120 | 190 | ||

LCK 120P | 300 | ||

LCK 155 | 450 | ||

LCK 155P | 700 | ||

Type Acceleration torque [Nm]

lck series

Bonfiglioli Low backlash right-angle gearboxes

![]()

LCK replicate in the right angle layout excellent features already typical of the inline products LC series. Right angle layout is the solution to space problems often posed by increasingly compact machines. This serie represent a flexible solution, and economic alternative together with an optimal performance and reliability.

Enhanced performance of our LCK precision gearboxes (“P” option) may open up important downsizing options as an option in many applications where previously was impossible to ensure a higher transmissible output torque.

As an additional benefit downsizing to an improvement of energy efficiency by selecting a more compact gearbox with higher torque density and reducing significantly the accelerating mass.

Transmissible torque is now improved up to 40%!!!

Torque range

10 ... 450 Nm

Maximum acceleration torque

20 ... 700 Nm

Transmission ratios

6 ... 100

Output configuration

Flange mounting

Input configuration

Wide range of coupling configurations to suit most common servomotors

Maintenance

Lubricated for life

Product Line Up

High Torque Density Option “P” available to extend the product performance Optimal Torque Density

Optimal Acceleration and Nominal Torques Optimal Radial and Axial Load Capacities Designed for Cyclic and Continuous Duty Optimal Torsional Stiffness

Geometrical Backlash less than 6 arcmin Universal design allow any Mounting Orientation

Backlash [arcmin]

Standard lower than 6 arcmin

mP series

Bonfiglioli Low backlash planetary gearboxes

![]()

MP planetary precision gearboxes are landmark for optimal performance, along with top reliability.

Available in different configuration (with input right angle; with output right angle; and hollow shaft, with solid input shaft), and servo-adapters to comply with most servomotors mechanical interface from the market.

Torque range

20 ... 1000 Nm

Maximum acceleration torque

30 ... 1200 Nm

Transmission ratios

3 ... 1000

Output configuration

Flange mounting

Input configuration

Wide range of coupling configurations to suit most common servomotors

Maintenance

Lubricated for life

Product Line Up

Higher Torque Density

Higher Acceleration and Nominal Torques Higher Radial and Axial Load Capacities Designed for Cyclic and Continuous Duty Higher Torsional Stiffness

Geometrical Backlash less than 10 arcmin

Highest flexibility (low / reduced backlash; standard / reinforced bearings; different constructive version) to match with your specific requirement.

Type Rated torque [Nm]

MP 053 | 20 | ||

MP 060 | 30 | ||

MP 080 | 70 | ||

MP 105 | 170 | ||

MP 130 | 450 | ||

MP 160 | 700 | ||

MP 190 | 1000 | ||

Type Acceleration torque [Nm]

MP 053 | 30 | ||

MP 060 | 45 | ||

MP 080 | 100 | ||

MP 105 | 250 | ||

MP 130 | 700 | ||

MP 160 | 950 | ||

MP 190 | 1200 | ||

Backlash [arcmin] Standard lower than 15 arcmin Reduced lower than 10 arcmin

Type Rated torque [Nm]

TR 053 | 20 | ||

TR 060 | 30 | ||

TR 080 | 70 | ||

TR 105 | 170 | ||

TR 130 | 450 | ||

TR 160 | 700 | ||

TR 190 | 1000 | ||

Type Acceleration torque [Nm]

TR 053 | 30 | ||

TR 060 | 45 | ||

TR 080 | 100 | ||

TR 105 | 250 | ||

TR 130 | 700 | ||

TR 160 | 950 | ||

TR 190 | 1200 | ||

Backlash [arcmin] Standard lower than 5 arcmin Reduced lower than 3 arcmin

tr series

Low backlash planetary gearboxes

![]()

TR planetary precision gearboxes are landmark for extremely reduced backlash, optimal performance, silent operation and facilitated motor assembly along with top reliability. Available in different configuration (with input right angle; with output right angle and hollow shaft; with solid input shaft), and servo-adapters to comply with most servomotors mechanical interface from the market.

Torque range

20 ... 1000 Nm

Maximum acceleration torque

30 ... 1200 Nm

Transmission ratios

3 ... 1000

Output configuration

Flange mounting

Input configuration

Wide range of coupling configurations to suit most common servomotors

Maintenance

Lubricated for life

Product Line Up

Higher Torque Density

Higher Acceleration and Nominal Torques Higher Radial and Axial Load Capacities Designed for Cyclic and Continuous Duty Higher Torsional Stiffness

Higher precision due to geometrical backlash less than 3 arcmin Quiet running

Highest flexibility (low / reduced backlash; standard / reinforced bearings; different constructive version) to match with your specific requirement.

Sl series

Low backlash planetary gearboxes

for pulley drives

![]()

SL planetary precision gearbox knows no rivals in compactness, efficiency and optimization for timing belt pulley drive systems.

This series is the ideal complement to conveyor belt servo-drives and all other applications needing to combine high precision with ultra-compact size.

Enhanced performance of our SL precision gearboxes (“P” option) may open up important downsizing options as an option in many applications where previously was impossible to ensure a higher transmissible output torque.

As an additional benefit downsizing lead to an improvement of energy efficiency by selecting a more compact gearbox with higher torque density and reducing significantly the accelerating mass.

Transmissible torque is now improved up to 40%!!!

Torque range

25 ... 155 Nm

Maximum acceleration torque

35 ... 300 Nm

Transmission ratios

3 ... 100

Output configuration

Flange mounting

Input configuration

Wide range of coupling configurations to suit most common servomotors

Maintenance

Lubricated for life

Product Line Up

High Torque Density Option “P” available to extend the product performance Higher Acceleration and Nominal Torques

Higher Radial and Axial Load Capacities Designed for Cyclic and Continuous Duty Higher Torsional Stiffness

Geometrical Backlash less than 6 arcmin Optionally available with a timing belt pulley. Quiet running

Universal design allow any mounting orientation

Type Rated torque [Nm]

SL 070 | 25 | ||

SL 070P | 30 | ||

SL 090 | 43 | ||

SL 090P | 65 | ||

SL 120 | 110 | ||

SL 120P | 155 | ||

Type Acceleration torque [Nm]

SL 070 | 35 | ||

SL 070P | 55 | ||

SL 090 | 80 | ||

SL 090P | 120 | ||

SL 120 | 190 | ||

SL 120P | 300 | ||

Backlash [arcmin]

Standard 12

Reduced 6

Type Rated torque [Nm]

KR 010 | 10 | ||

KR 020 | 24 | ||

KR 030 | 55 | ||

KR 040 | 120 | ||

Type Acceleration torque [Nm]

KR 010 | 14 | ||

KR 020 | 35 | ||

KR 030 | 75 | ||

KR 040 | 170 | ||

Backlash [arcmin]

Standard 8

kr series

Bonfiglioli Low backlash right-angle gearboxes

![]()

Flexible, efficient economical solution to applications calling for space saving right angle drives with minimal backlash.

Available in different configurations with numerous input and output configuration.

Torque range

3 ... 120 Nm

Maximum acceleration torque

14 ... 170 Nm

Transmission ratios

1, 2, 5

Output configuration

Hollow shaft with keyway

Solid shaft, single or double sided Hollow shaft with shrink disc Mounting flange

Input configuration

Wide range of coupling configurations to suit most common servomotors

Maintenance

Lubricated for life

Product Line Up

Best combination of Dynamics, Compactness and Precision Designed for Cyclic and Continuous Duty

Good Torsional Stiffness

Geometrical Backlash less than 8 arcmin

tq series

Bonfiglioli Low backlash planetary gearboxes

![]()

TQ features a higher positioning. Whether torque, robustness, or precision - this attractive product range scores in every category.

Torque range

30 ... 800 Nm

Maximum acceleration torque

45 ... 1200 Nm

Transmission ratios

3 ... 100

Output configuration

Square flange mounting

Input configuration

Wide range of coupling configurations to suit most common servomotors

Maintenance

Lubricated for life

Product Line Up

Outstanding Torque Density

Outstanding Acceleration and Nominal Torques Outstanding Radial and Axial Load Capacities Designed for Cyclic and Continuous Duty Markedly higher Torsional Stiffness

Extremely Geometrical Backlash less than 2 arcmin Quiet running

Universal design allow any mounting orientation

Type Rated torque [Nm]

TQ 060 | 30 | ||

TQ 070 | 70 | ||

TQ 090 | 200 | ||

TQ 130 | 400 | ||

TQ 160 | 800 | ||

Type Acceleration torque [Nm]

TQ 060 | 45 | ||

TQ 070 | 100 | ||

TQ 090 | 300 | ||

TQ 130 | 600 | ||

TQ 160 | 1200 | ||

Backlash [arcmin] Standard lower than 4 arcmin Reduced lower than 2 arcmin

Type Rated torque [Nm]

TQK 060 | 30 | ||

TQK 070 | 70 | ||

TQK 090 | 200 | ||

TQK 130 | 400 | ||

TQK 160 | 800 | ||

Type Acceleration torque [Nm]

TQK 060 | 45 | ||

TQK 070 | 100 | ||

TQK 090 | 300 | ||

TQK 130 | 600 | ||

TQK 160 | 1200 | ||

Backlash [arcmin] Standard lower than 5 arcmin Reduced lower than 4 arcmin

tqk series

Bonfiglioli Low backlash right-angle gearboxes

![]()

TQK angular gearbox features a higher positioning like TQ inline serie.

This exceptional gearbox is the solution to space problems often posed by increasingly compact machines.

Whether torque, robustness, or precision - this attractive product range scores in every category.

Torque range

30 ... 800 Nm

Maximum acceleration torque

45 ... 1200 Nm

Transmission ratios

3 ... 100

Output configuration

Square flange mounting

Input configuration

Wide range of coupling configurations to suit most common servomotors

Options

Smooth, keyless output shaft

Maintenance

Lubricated for life

Product Line Up

Outstanding Torque Density

Outstanding Acceleration and Nominal Torques Outstanding Radial and Axial Load Capacities Designed for Cyclic and Continuous Duty Markedly higher Torsional Stiffness

Extremely Geometrical Backlash less than 4 arcmin Quiet running

Universal design allow any mounting orientation

bn/m series

Bonfiglioli AC motors

A complete range of AC motors developed for gearmotor duty that will exceed expectations.

The IEC-normalized BN motors comply with all the applicable international standards, including the EMC and LV Directives. They are available in the 0.06 - 30 kW range in the foot and the flange mounting version, the latter in both the IM B5 and the IM B14 configuration. Single and multispeed versions available with generally, three brake options offered, one DC and two AC supply, lending further flexibility to the system. Finally, all motors are inverter duty.

kW rating (4 pole)

0.06 ... 30 kW

Frame sizes

56A ... 200L

Pole numbers

2, 4, 6, 8, 2/4, 2/6, 2/8, 2/12, 4/6, 4/8

Mounting options

Foot IM B3

Flange IM B5 and IM B14

Operation

50 Hz and 60 Hz

Compliance

2006/95/EC (LVD) and 2004/108/EC (EMC)

Inverter duty

All frame sizes

Housing

Cast aluminium

Main brake features

DC and AC supply

Faster brake engage/disengage through electronically Controlled AC/DC rectifier type NB, SB, NBR, SBR (options)

Main options

Thermistors and thermostat sensors Separate supply forced ventilation

Line driver and push-pull incremental encoder CSA and UL approved design

BN 56A | 0.06 | ||

BN 56B | 0.09 | ||

BN 63A | 0.12 | ||

BN 63B | 0.18 | ||

BN 63C | 0.25 | ||

BN 71A | 0.25 | ||

BN 71B | 0.37 | ||

BN 71C | 0.55 | ||

BN 80A | 0.55 | ||

BN 80B | 0.75 | ||

BN 80C | 1.1 | ||

BN 90S | 1.1 | ||

BN 90LA | 1.5 | ||

BN 90LB | 1.85 | ||

BN 100LA | 2.2 | ||

BN 100LB | 3 | ||

BN 112M | 4 | ||

BN 132S | 5.5 | ||

BN 132MA | 7.5 | ||

BN 132MB | 9.2 | ||

BN 160MR | 11 | ||

BN 160M | 15 | ||

BN 180M | 18.5 | ||

BN 180L | 22 | ||

BN 200L | 30 | ||

Type kW rating

be/me series

IE2 AC motors

![]()

![]()

Class IE2 high efficiency AC motors.

The IEC-normalized BE motors comply with IEC 60034-30:2008 (efficiency classes) and all the applicable international standards, including the EMC and LV Directives.

They are available in the 0.75 - 22 kW range in the foot and the flange mounting version, the latter in both the IM B5 and the IM B14 configuration. Single version is available

with generally, two brake options offered, one DC and one AC supply, lending further flexibility to the system. Finally, all motors are inverter duty.

IE2

BE 80B | 0.75 | ||

BE 90S | 1.1 | ||

BE 90LA | 1.5 | ||

BE 100LA | 2.2 | ||

BE 100LB | 3 | ||

BE 112M | 4 | ||

BE 132S | 5.5 | ||

BE 132MA | 7.5 | ||

BE 132MB | 9.2 | ||

BE 160M | 11 | ||

BE 160L | 15 | ||

BE 180M | 18.5 | ||

BE 180L | 22 | ||

Type kW rating

kW rating (4 pole)

0.75 ... 22 kW

Frame sizes

80B ... 180L

Pole numbers

2, 4, 6

Mounting options

Foot IM B3

Flange IM B5 and IM B14

Operation

50 Hz and 60 Hz

Compliance

IEC 60034-30:2008 (IE), 640/2009/EC 2006/95/EC (LVD) and 2004/108/EC (EMC)

Inverter duty

All frame sizes

Housing

Cast aluminium

Main brake features

DC and AC supply

Faster brake engage/disengage through electronically Controlled AC/DC rectifier type NB, SB, NBR, SBR (options)

Main options

Thermistors and thermostat sensors Separate supply forced ventilation

Line driver and push-pull incremental encoder CSA and UL approved design

bx/mx series

Bonfiglioli New IE3 Motors

![]()

![]()

The release of the new BX/MX motors is a further expression of our sensitiveness to the environment preservation.

The BX/MX motors fulfil the requirements of IE3 efficiency class, according to the international standard IEC 60034-30.

The “X” of the new BX/MX motors stands for “excellence” in efficiency, being IE3 the top efficiency rating currently formalized by global standards.

IE3

Power Range (4 pole)

5.5 ... 22 kW

Frame Sizes

132S ... 180L

Pole Numbers

4

Mounting Options

Foot IM B3

Flange IM B5 and IM B14

Operation

50 Hz

Compliance

IEC 60034-30:2008 (IE),

2006/95/EC (LVD) and 2004/108/EC (EMC)

Inverter Duty

All frame sizes

Housing

Cast aluminium

Main Options

Thermistors and thermostat sensors Separate supply forced ventilation

Line driver and push-pull incremental encoder CSA and UL approved design

BX 132S | 5.5 | ||

BX 132MA | 7.5 | ||

BX 160MA | 9.2 | ||

BX 160MB | 11 | ||

BX 160L | 15 | ||

BX 180M | 18.5 | ||

BX 180L | 22 | ||

Type kW rating

bS series

Single-phase induction motors

A range of motors dedicated to domestic and light workshop duty.

Single-phase motors of the BS series are manufactured to the applicable IEC standards and are of the enclosed type, externally ventilated and with run capacitor permanently connected.

Motors are available in the B5 and B14 flange mountings, in the 4-pole execution.

For applications requiring high starting torque the version with both the run and starting capacitor can be specified.

BS 56A | 0.06 | ||

BS 56B | 0.09 | ||

BS 63A | 0.12 | ||

BS 63B | 0.18 | ||

BS 71A | 0.25 | ||

BS 71B | 0.37 | ||

BS 80A | 0.55 | ||

BS 80B | 0.75 | ||

BS 90S | 1.1 | ||

BS 90L | 1.5 | ||

Type kW rating

kW ratings

0.06 … 1.5 kW

Frame sizes

56A to 90L

Poles

4

Mounting

Flange mounting IM B5 and IM B14

Frequency

50 and 60 Hz

European norms

2006/95/EC (LVD) and 2004/108/EC (EMC)

Housing

Cast Aluminium

Main options

Starting and run capacitors Bimetal thermal protector Balanced winding

bc series

Bonfiglioli DC motors

A comprehensive range of permanent magnet DC motors.

The BC series of motors are the simple, proven and economical solution to the requirements of DC drives. The materials and the design concepts exploited allow the use of BC motors under the severest duty and with 4-quadrants thyristor converters.

Motors can be operated in the –20 to +40 °C ambient temperature range and are IP54 protected and class F insulated.

Torque range

0.3 ... 4.5 Nm

Speed

1500, 2000, 3000 min-1

Supply

12, 24, 36, 48,65, 110, 180, Vdc

Configurations

IM B5 and IM B14 Flange Mount

Ventilation

BC110 ... BC140 non-ventilated BC220 ... BC310 TEFC

BC 110 | 0.3 | ||

BC 120 | 0.8 | ||

BC 140 | 1.4 | ||

BC 220 | 0.9 | ||

BC 240 | 1.2 | ||

BC 270 | 2.2 | ||

BC 310 | 4.5 | ||

Type Torque [Nm]

![]()

BMD 65 0.85 | 0.85 | ||

BMD 65 1.7 | 1.7 | ||

BMD 65 2.2 | 2.2 | ||

BMD 82 3.2 | 3.2 | ||

BMD 82 4.4 | 4.4 | ||

BMD 102 7.2 | 7.2 | ||

BMD 102 9.6 | 9.6 | ||

BMD 118 10.2 | 10.2 | ||

BMD 118 14 | 14 | ||

BMD 145 16.8 | 16.8 | ||

BMD 145 22 | 22 | ||

BMD 170 34 | 34 | ||

BMD 170 45 | 45 | ||

BMD 160 L | 125 | ||

Type Torque [Nm]

bmd series

Permanent Magnet AC servomotors

![]()

Bonfiglioli Permanent Magnet AC Synchronous motors series.

They are manufactured using the “salient pole” technology. The dimensions of the motor are drastically reduced, with considerable advantages in terms of torque density, overall dimensions and dynamic performance.

Thanks to the high quality and performance of the Neodymium iron boron rare-earth magnets maximize performance in terms of very high accelerations and withstand high overloads without risk of demagnetization of the magnets.

Stall torque

0.85 … 125 Nm

Rated speed

1600; 3000; 4500; 5500; 6000 min-1

Power supply

230, 400 Vac

Conformity

2006/95/EC (LVD) and 2004/108/EC (EMC)

Electromagnetical Holding Brake (Optional)

24 Vdc

Inertia

High acceleration capacity due to lower motor moment of inertia

Additional flywheel (optional)

Excellent behavior with superior load inertia due to the high intrinsec moment of inertia

Feedback

poles resolver with excitation frequency 8 KHz or 10 KHz

Absolute encoder EnDAT 2.1 (single turn / multiturn) encoder with sincos track Absolute encoder Hiperface (single turn / multiturn) encoder with sincos track Sensorless (no feed-back)

Degree of protection

IP65 IP67

Temperature sensor

PTC KTY

Certification

CE, UL

btd series

Bonfiglioli Compact AC brushless servomotors

A range of compact servomotors.

BTD Series servomotors are designed to provide effective solutions for applications demanding high efficiency, compact motors.

The extremely small size of these motors, achieved by the use of advanced materials and design technology, ensures exceptional dynamics and low temperature operation. Equipped with IP65 push-pull connectors (IP67 connectors are optional), in conformity to EMC requirements, and a PTC temperature probe with reinforced insulation, these motors guarantee secure electrical connections under a huge variety of operating conditions.

Stall torque

0.26 … 27 Nm

Rated speed

3000, 4500 min-1

Power supply

230, 400 Vac

Inertia

High acceleration capacity due to lower motor moment of inertia

Conformity

2006/95/EC (LVD) and 2004/108/EC (EMC)

Electromagnetical Holding Brake (Optional)

24 Vdc

Feedback

2-poles resolver with excitation frequency 5 KHz or 10 KHz

Absolute encoder EnDAT 2.1 (single turn / multiturn) encoder with sincos track Absolute encoder Hiperface (single turn / multiturn) encoder with sincos track

Temperature sensor

PTC

Certification

CE, UL

BTD2 0026

0.26

BTD2 0053

0.53

BTD2 0074

0.74

BTD2 0095

0.95

BTD3 0095

0.95

BTD3 0190

1.9

BTD3 0325

3.25

BTD3 0420

4.2

BTD4 0410

4.1

BTD4 0630

6.3

BTD4 0860

8.6

BTD5 1160

11.6

BTD5 1490

14.9

BTD5 1870

18.7

BTD5 2730

27.3

Type Torque [Nm]

Type Torque [Nm]

bcr series

AC brushless servomotors

A range of high performance servomotors.

BCR Series servomotors are designed to satisfy the needs of continuous and transient high torque applications. Thanks to a wide torque range and above average instantaneous overload ratings, BCR servomotors are robust enough for even the most demanding drive applications. Equipped with IP65 push-pull connectors (IP67 connectors are optional), in conformity to EMC requirements, and with a PTC temperature probe with reinforced insulation, these motors guarantee a secure electrical connection under a huge variety of operating conditions.

Stall torque

0.2 … 115 Nm

(High instantaneous overload)

BCR2 0020

BCR2 0040

BCR2 0060

BCR2 0080

BCR3 0065

BCR3 0130

BCR3 0250

BCR3 0300

BCR4 0100

BCR4 0260

BCR4 0530

BCR4 0750

BCR5 0660

0.2

0.4

0.6

0.8

0.65

1.3

2.5

3

1

2.6

5.3

7.5

6.6

Rated speed

2000, 3000, 4500 rpm

Power supply

230, 400 Vac

Inertia

High acceleration capacity due to lower motor moment of inertia

Conformity

2006/95/EC (LVD) and 2004/108/EC (EMC)

Electromagnetical Holding Brake (Optional)

Optional 24 Vdc

BCR5 1050

10.5

Feedback

2-poles resolver with excitation frequency 5 KHz or 10 KHz

BCR5 1350

BCR5 1700

13.5

17

Absolute encoder EnDAT 2.1 (single turn / multiturn) encoder with sincos track Absolute encoder Hiperface (single turn / multiturn) encoder with sincos track

BCR5 2200

22

BCR6 1350

13.5

Temperature sensor

PTC

BCR6 1900

19

BCR6 2200

22

Certification

BCR6 2900

29

CE, UL

BCR7 2700

27

BCR7 3200

32

BCR7 4000

40

BCR8 0400

40

BCR8 0680

68

BCR8 0930

93

BCR8 1150

115

agile series

Bonfiglioli Inverter

Innovative, eco-friendly, user-friendly.

Agile series provide in a sensorless vector inverter innovations able to boost plant efficiency through open loop vector control of brushless motors and MMC memory cards. Agile inverters are easy to install, program and quick to start-up without the needs of specialized resources.

Power range (AGL402)

0.25 ... 11 kW / three-phase 320-530V / 50-60 Hz (± 10%)

Type Power kW

Power range (AGL202)

0.12 ... 3 kW / single phase 200-240V / 50-60 Hz (± 10%)

0.25 ... 7.5 kW / three-phase 200-240V / 50-60 Hz (± 10%)

Motor compatibility Two types of motor: Asynchronous AC motors

Permanent magnet synchronous (brushless) motors

Type of control

Selectable control function:

V/f control for asynchronous motors

Sensor-less vector control for asynchronous motors Sensor-less vector control for brushless motors

Degree of protection

IP20 (EN 60529)

Main hardware features

Power supply from common DC bus

AGL402-18

4.0

AGL402-19

5.5

AGL402-21

7.5

AGL402-22

9.2

AGL402-23

11

AGL402-02 AGL402-03 AGL402-05 AGL402-07 AGL402-09 AGL402-11 AGL402-13 AGL402-15

0.25

0.37

0.55

0.75

1.1

1.5

2.2

3.0

Integrated braking module

Short circuit / ground fault protection

Type Power kW (3ph)

Integrated Safe Torque Off safety system Plug-in and programmable control terminals 6 digital inputs, 2 multifunctional A/D inputs 1 multifunctional I/O, 1 digital output

1 multifunctional A/D/pulse output, 1 relay output (alarm) available power outputs: +24 V DC, +10 V DC

optional separate 24 V DC electronic power supply standard serial interfaces: RS232, RS485, Systembus Integrated Modbus

Optional expansion modules

Resource Pack memory card

Optional communication modules

PROFIBUS-DPV1, CANopen, RS232, RS485, DeviceNet, EtherCAT®, PROFINET, VABus/

TCP*, Modbus TCP*, EtherNet I/P

AGL202-02 AGL202-03 AGL202-05 AGL202-07 AGL202-09 AGL202-11 AGL202-13 AGL202-15 AGL202-18 AGL202-19 AGL202-21

0.25

0.37

0.55

0.75

1.1

1.5

2.2

3.0

4.0

5.5

7.5

PC software

VPlus suite

Main software features

Permanent motor tuning

Selective Multi-Motor Control (SMMC) Energy saving function

Ready to use application masks Integrated maintenance wizard Alarm history

Motor and inverter state memory Autodiagnostics

Integrated PLC function with graphic development environment Integrated oscilloscope function

Customisable units of measurement

(*) Optional 2 ports.

AGL202-02

0.12

AGL202-03

0.18

AGL202-05

0.25

AGL202-07

0.37

AGL202-09

0.55

AGL202-11

0.75

AGL202-13

1.1

AGL202-15

1.5

AGL202-18

2.2

AGL202-19

3

AGL202-21

3

Type Power kW (1ph)

ACT401-05

0.55

ACT401-07

0.75

ACT401-09

1.1

ACT401-11

1.5

ACT401-12

1.85

ACT401-13

2.2

ACT401-15

3.0

ACT401-18

4.0

ACT401-19

5.5

ACT401-21

7.5

ACT401-22

9.2

Type Power kW

active series

Bonfiglioli Solution Drive

Versatility, rating, performances.

A full series of flexible solution drives that are versatile and extremely easy to use, featuring control for high performance and unbeatable advantages in their scalability and compact size.

Power range (ACT401)

0.55 ... 132 kW / three-phase 360-480V / 50-60 Hz (± 10%)

Power range (ACT201)

0.55 ... 9.2 kW / single or three-phase 200-240V / 50-60 Hz (± 10%)

Type of control

Selectable Vector control function:

sensor-less control, sensor-less field oriented control, field oriented control with encoder

Overload capacity

150% for 60s / 200% for 1s

Switching frequency

2, 4, 8, 12, 16 kHz

Enclosure

IP20 (EN 60529)

ACT401-23

11

ACT401-25

15

ACT401-27

18.5

ACT401-29

22

ACT401-31

30

ACT401-33

37

ACT401-35

45

ACT401-37

55

ACT401-39

65

ACT401-43

75

ACT401-45

90

ACT401-47

110

ACT401-49

132

EMC filter

Integrated up to 9.2 kW (EN 61800-3)

Main standard hardware features

Integrated dynamic braking module, DC link connection, Standard encoder interface, Motor temperature monitoring, Plug-in power terminals (up to 3kW), Plug-in and programmable control terminals, 6 digital input, 1 multifunction input, 1 digital output, 1 multifunction Output, 1 relay output (changeover contact)

Optional expansion modules

Expansion of analog, digital inputs and outputs, additional encoder or resolver input, repetition frequency output, System bus

Optional communication modules

RS232, RS485, PROFIBUS-DP, CANopen

Optional keypad

ACT201-05

0.55

ACT201-07

0.75

ACT201-09

1.1

ACT201-11

1.5

ACT201-13

2.2

ACT201-15

3.0

ACT201-18

4.0

ACT201-19

5.5

ACT201-21

7.5

ACT201-22

9.2

Removable keypad KP500 with copy function, Cabinet mounting kit and handheld for keypad

Optional PC software

VPlus for Windows operating system with set-up, terminal monitor, actual value window, scope function and teleservice

Main software features

Programmable reference value channel, Programmable start and stop characteristics, Motor potentiometer, Programmable S curve, 4 data sets, Auto start-up and commissioning, Auto reset after failure, Auto start after power failure, PI controller, Programmable logic and timer functions, Volume flow control, Bump-less torque / speed changeover, Master / Slave function with electronic gear, Enhanced positioning function, Mechanical brake control free of friction, Index and stability control, Intelligent current limits, Power failure regulation, Comprehensive monitoring and protection capabilities, High speed control, Function for lift, crane and winch applications, 3 different brake Management Functions.

active cube series

Bonfiglioli Solution & Servo Drive

Versatility, promptness, accuracy.

A full series of solution & servo drives, compact and flexible, dedicated both to high demanding industrial automation systems and to speed and positioning control architectures, all matched with Bonfiglioli servomotors.

Power range (ACU401)

0.25 ... 132 kW / three-phase 360 ... 480V / 50-60 Hz (± 10%)

Power range (ACU201)

0.25 ... 9.2 kW / single or three-phase 200 ... 240V / 50-60 Hz (± 10%)

Type of control

Selectable Vector control function: sensor-less control, sensor-less field oriented control, field oriented control with speed sensor, field oriented control of synchronous servomotors with speed/position sensor

Overload capacity

200% for 1min (size 01 and 03) / 150% for 1min (other ratings), Shorter overload: 200% for 1sec all ratings

Switching frequency

2, 4, 8, 12, 16 kHz

Enclosure

IP20 (EN 60529)

EMC filter

Integrated up to 9.2 kW (EN 61800-3)

Main standard hardware features SIL2

Integrated safe torque off function, External 24Vdc supply for control board and electronics, Integrated dynamic braking module, DC link connection, Standard encoders interface, Resolver module for feedback acquisition from Bonfiglioli servomotors, Motor temperature monitoring, Plug-in power terminals (up to 3kW), Plug-in and programmable control terminals 6 digital input, 1 multifunction input, 1 digital output, 1 multifunction, Output, 1 relay output (changeover contact)

Optional expansion modules

Expansion of analog, digital inputs and outputs, additional encoder or resolver input and SinCos, Hiperface or EnDat 2.1 Encoder, repetition frequency output, System bus

Optional communication modules

PROFIBUS-DPV1, CANopen, RS232, RS485, DeviceNet, EtherCAT®, PROFINET, VABus/TCP*,

Modbus TCP*, EtherNet I/P

Optional keypad

Removable keypad KP500 with copy function, Cabinet mounting kit and handheld for keypad

ACU201-01

0.25

ACU201-03

0.37

ACU201-05

0.55

ACU201-07

0.75

ACU201-09

1.1

ACU201-11

1.5

ACU201-13

2.2

ACU201-15

3.0

ACU201-18

4.0

ACU201-19

5.5

ACU201-21

7.5

ACU201-22

9.2

PC software VPlus

Vplus software provides a common programming and monitoring platform for all Bonfiglioli inverter drives. Easy programming interface with real time oscilloscope. A simple and guided procedure for set up with Bonfiglioli Motors. Logic functions programming. Teleservice.

Main software features

32 Programmable Motion blocks, 36 Homing functions according to CANopen DSP4.02, Unit converter, Jog function, Absolute and relative positioning modes, Touch probe, Teach- In functions, Rotary table control, Programmable reference value channel, Programmable start and stop characteristics, Motor potentiometer, Programmable S curve, 4 data sets, Auto start-up and commissioning, Auto reset after failure, Auto start after power failure, PI controller, Programmable logic and timer functions, Bump less torque / speed changeover, Master / Slave function with electronic gear, Index and stability control, Intelligent current limits, Power failure regulation, Comprehensive monitoring and protection capabilities, High speed control, Function for lift, crane and winch applications, 3 different brake Management

Functions. Advanced application functions: advanced brake release control, spindle control up to 1000Hz, traverse function for winders, Volume flow control, load evaluation.

(*) Optional 2 ports.

ACU401-01

0.25

ACU401-03

0.37

ACU401-05

0.55

ACU401-07

0.75

ACU401-09

1.1

ACU401-11

1.5

ACU401-12

1.85

ACU401-13

2.2

ACU401-15

3.0

ACU401-18

4.0

ACU401-19

5.5

ACU401-21

7.5

ACU401-22

9.2

ACU401-23

11

ACU401-25

15

ACU401-27

18.5

ACU401-29

22

ACU401-31

30

ACU401-33

37

ACU401-35

45

ACU401-37

55

ACU401-39

65

ACU401-43

75

ACU401-45

90

ACU401-47

110

ACU401-49

132

Type Power kW

Type Power kW

ACU401-51

160

ACU401-53

200

ACU401-55

250

ACU401-57

315

ACU401-59

355

ACU401-61

400

Rated voltage: 400V

Type Power kW

ACU601-51

160

ACU601-53

200

ACU601-55

250

ACU601-57

315

ACU601-59

355

ACU601-61

400

Rated voltage: 690V

active cube series - Size 8

Bonfiglioli Solution & Servo Drive

Energy efficient, versatile and compact.

A full series of solution & servo drives, compact and flexible, dedicated both to high demanding industrial automation systems and to motion control architectures, prepared to operate energy efficient synchronous and asynchronous motors with and without speed sensor.

Power range (ACU401)

160 ... 400 kW / three-phase 380 V (-15%) ... 480 V (+10%) / 50 - 60 Hz (± 10%)

Power range (ACU601)

160 ... 400 kW / three-phase 500 ... 690 V (±10%) / 50 - 60 Hz (± 10%)

Type of control

Selectable Vector control function: sensor-less control, sensor-less field oriented control, field oriented control with speed sensor, field oriented control of synchronous servomotors with speed/position sensor

Overload capacity

150% for 1min

Shorter overload: 180% for 1sec all ratings

Switching frequency

2, 4, 8 kHz

Enclosure

IP20 (EN 60529)

EMC filter

External filter

Main standard hardware features SIL2

Integrated safe torque off function, External 24Vdc supply for control board and electronics, Integrated dynamic braking module, DC link connection, Standard encoders interface, Resolver module for feedback acquisition from Bonfiglioli servomotors, Motor temperature monitoring, Plug-in power terminals (up to 3kW), Plug-in and programmable control terminals 6 digital input, 1 multifunction input, 1 digital output, 1 multifunction, Output, 1 relay output (changeover contact), 1 additional relais for external precharge, possibility for a 3-level-concept, possibility for a 12-pulse-rectifire-concept

Optional expansion modules

Expansion of analog, digital inputs and outputs, additional encoder or resolver input and sincos encoder, repetition frequency output, System bus

Optional communication modules

Profibus-DP, CANopen, RS232, RS485, DeviceNet, EtherCAT®, ProfiNet, Ethernet VA BUS TCP

Optional keypad

Removable keypad KP500 with copy function, Cabinet mounting kit and handheld for keypad

PC software VPlus

Vplus software provides a common programming and monitoring platform for all Bonfiglioli inverter drives. Easy programming interface with real time oscilloscope. A simple and guided procedure for set up with Bonfiglioli Motors. Logic functions programming. Teleservice.

Main software features

32 Programmable Motion blocks, 36 Homing functions according to CANopen DSP4.02, Unit converter, Jog function, Absolute and relative positioning modes, Touch probe, Teach-In functions, Rotary table control, Programmable reference value channel, Programmable start and stop characteristics, Motor potentiometer, Programmable S curve, 4 data sets, Auto start- up and commissioning, Auto reset after failure, Auto start after power failure, PI controller, Programmable logic and timer functions, Bump less torque / speed changeover, Master / Slave function with electronic gear, Index and stability control, Intelligent current limits, Power failure regulation, Comprehensive monitoring and protection capabilities, High speed control, Function for lift, crane and winch applications, 3 different brake Management Functions. Advanced application functions: advanced brake release control, spindle control up to 500Hz, traverse function for winders, Volume flow control, load evaluation.

vcb series

Bonfiglioli Inverter

Convenient in operation and flexible in application.

Reliable, highly compact and a robust choice for any application, this inverter with high- level functions soundly meets the requirements of a constantly evolving market.

Power range (VCB400)

132 ... 800 kW / three-phase 320-506V / 45-66 Hz

Type of control

Selectable Vector control function:

Sensor-less control, sensor-less field oriented control, Field oriented control with encoder

Overload capacity

120% / 150% for 60s

Switching frequency

kHz up to 4 kHz

Enclosure

IP20 up to 355 kW (EN 60529) / IP54 on demand

Main standard hardware features

Three-phase 230 V and three-phase 500 V on demand

DC link connection, Plug-in and programmable control terminals 8 digital input, 3 analog input

digital output, 1 analog output

1 Relay output (changeover contact)

Optional expansion modules

Motor temperature monitoring, expansion of analog, digital inputs and outputs, additional encoder or resolver input, repetition frequency output, Safety relay in combination with expansion module

Optional communication modules

RS232, RS485, PROFIBUS-DP, CANopen, LON

Optional keypad

Removable keypad KP100

Optional PC software

VPlus for Windows operating system with set-up, terminal monitor, actual value window, scope function and teleservice

Main software features

Programmable reference value channel, Programmable start and stop characteristics, Motor potentiometer, Programmable S curve, 4 data sets, Auto start-up and commissioning, Auto start after power failure, PI controller, Volume flow control, Bump- less torque / speed changeover, Master / Slave function with electronic gear, Dynamic braking and motor chopper, Mechanical brake control free of friction, Intelligent current limits, Power failure regulation, Index and stability control, Comprehensive monitoring and protection capabilities, Function for lift, crane and winch applications

VCB400-250

132

VCB400-300

160

VCB400-370

200

VCB400-460

250

VCB400-570

315

VCB400-610

355

Type Power kW

S2U230S-02

0.20

S2U230S-03

0.40

S2U230S-07

0.75

S2U230S-11

1.5

S2U230S-13

2.2

Type Power kW

S2u series

Bonfiglioli Variable Frequency Drive

The Ideal drive for your lean application projects.

Intuitive and simple, but powerful and effective.

S2U is the Bonfiglioli Vectron compact Inverter for efficient speed and torque control of electric motors, up to 2.2kW.

The simple installation and use, together with connectivity and outstanding range of functions, make it the the perfect drive for the control of those applications where productivity and short time to market are critical.

Power range

0.20 ... 2.2 kW / single-phase 200-240V / 50-60 Hz (+10, -15%)

Type of control

V/F control with automatic torque compensation function

Overload capacity

150% for 60s

Switching frequency

1-16 kHz

Enclosure

IP20

EMC filter

Integrated Class C2 filter

Main standard hardware features

5 models In 2 frame sizes

2 Analog Input (0-10V and 0-20 or 4-20mA) 5 Digital Input (programmable multifunction)

1 Analog Output (programmable multifunction). 1 Relay output (programmable multifunction).

RJ45 terminal for communication with PC.

Keypad

Built-in standard keypad with potentiometer

Main functions

100% configuration compatibility with Bonfiglioli Synthesis series Selectable auto re-start after power loss

acc/dec times - 4 S curves available Overload detection

PID control Torque boost Stall prevention

Motor temperature protection Heat sink overheat protection Selectable stop method

JOG frequency Alarm history

Short power loss override Output Short-Circuit protection DC injection braking.

Auto sequencer. 8 preset speeds and 8 preset times. Momentary power loss start

Auot restart after fault. 10 attempts. Direct start on Power up

Parameter access lock

bmI series

Bonfiglioli Human Machine Interfaces

Human Machine Interface solution suitable for any environment.

The new Bonfiglioli Human Machine Interface series offers high performance and quality at affordable price. In combination with PLC functionality integrated in Inverters of Agile and Active Cube Series Bonfiglioli offers a high performance and cost effective solution for many applications which can be controlled directly by drives functionality without need of PLC.

Key Features

3 Display sizes – 3.5”, 7” and 10”

Robust ABS plastic chassis

True Flat front panel in IP65

High resolution 480 x 272 up to 1024 x 600 Pixels

65.536 Colours

Ethernet communication port as standard

Optional Field bus communications for IT series

Applications

Textile

Cranes

Wood

Material Handling

Packaging

Paper

Plastic

Energy