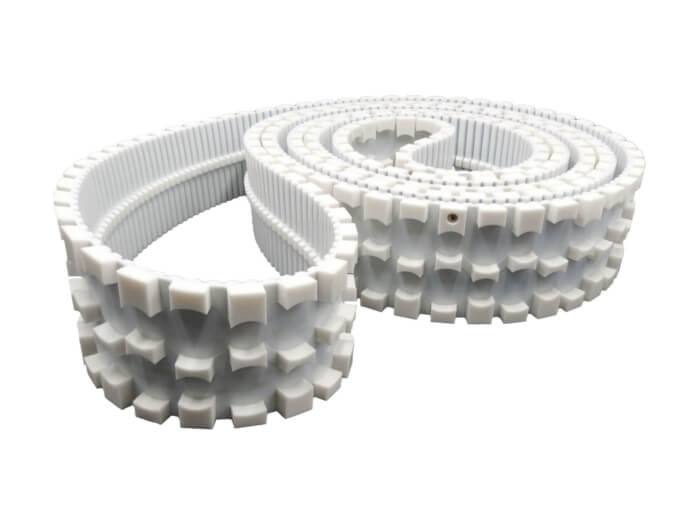

Timing Belts with False Teeth

The most commonly adopted solution for synchronous product transport in recent years has been timing belts equipped with mechanical false teeth and corresponding attachments. By replacing the belt’s teeth with threaded stainless-steel components, various attachments or devices of different shapes and materials can be securely fastened to its back. The positioning of the fastening bushes can be customized to the required spacing, while the distance between the attachments, determined by the customer, must always be a multiple of the belt pitch.

False tooth technology

False tooth technology enables timing belts to be converted into a highly reliable synchronous transport system, combining the durability of mechanical components with the versatility of material selection for attachments. Timing belts featuring stainless steel (AISI 304) false teeth are extensively utilized in automatic machinery, packaging, and industrial automation sectors.

Mechanical Attachments

In addition to timing belts with false teeth, mechanical attachments can be supplied pre-assembled on the system, with customizable geometry and material options to best suit the specific application. For applications requiring a more robust and rigid system, we offer metal mechanical attachments. The most commonly used materials include ALUMINUM, STEEL, and STAINLESS STEEL, which can undergo various treatments such as ANODIZATION, GHA, ALODINE, NICKEL PLATING, GALVANIZATION, and PHOSPHATING.

Timing Belts with cleats

In recent years, the variety of packaging solutions on the market has grown exponentially, increasing the demand for attachments with highly specific shapes. Thanks to our extensive experience, we can provide attachments in any geometry. Timing belts with cleats are commonly used in high-speed, precision conveyor systems, particularly in the fields of automatic machinery, packaging, and industrial automation.

Polyurethane attachments with metal inserts

Thermoplastic polyurethane (TPU) attachments are mounted onto the timing belt and can be welded to the back at any position, giving customers full flexibility in determining the spacing. Unlike belts with false teeth, the attachment placement does not need to be a multiple of the tooth pitch.

Dovetail Attachments

Conveyor timing belts are frequently exposed to high acceleration forces, and the specific weight of polyurethane can sometimes prevent the desired geometry from being achieved due to excessive attachment weight. By welding a dovetail attachment to the back of the belt, a secondary attachment made from a lighter material—such as glass-fiber reinforced plastic or carbon fiber—can be securely fitted through an interference connection.

Attachments with Brushes

For transporting fragile objects, rigid attachments are not suitable as they may compromise product integrity. By designing perforated attachments, brushes can be inserted to create a soft belt surface, allowing delicate items to be gently transported without risk of damage.

Timing Belts for Packaging Machines (VFFS)

One of the main industries utilizing this solution is packaging, particularly in packaging machines where a film or wrapping reel is guided onto a former tube by two coated timing belts. Given the vast variety of packaging types available, selecting a single coating to optimize machine performance is challenging. To address this, we have studied different material blends and hardness levels to best meet customers’ specific requirements.

The advantages of silicone rubber

Silicone rubber offers several advantages, including a significantly extended belt lifespan, often doubling or tripling depending on the film used. Its softness and elasticity enhance grip, allowing for higher film unwinding speeds compared to other materials. Unlike synthetic rubber, which dries out and loses performance over time, silicone rubber maintains consistent efficiency. Additionally, while natural rubber requires cold gluing and limits movement to one direction, silicone rubber is hot-molded, enabling bidirectional movement and ensuring strong adhesion between the belt and coating. Its resistance to extreme temperatures, ranging from 0°C to 180°C, further enhances its durability.

Belts for Vacuum Systems

To achieve optimal performance, packaging machines are often equipped with vacuum systems. When combined with timing belts custom-machined to specific design requirements, these systems can significantly increase the machine’s cycle count and overall efficiency.

Timing Belts with Cover

A wide range of coatings can be applied to the back of timing belts, and based on your specific application requirements, we can recommend the most suitable solution both technically and economically. Coated belts are utilized across various industries, including packaging, glass, wood, ceramics, automation, and food processing. Depending on the product being transported, coatings with varying hardness levels and characteristics are chosen to provide the optimal grip.

Cold-Glued Coatings

Hot Vulcanised Coatings

Silicone and Silicone Rubber Coatings

Extruded Coatings on Timing Belts

Foam Coatings and Dual Coatings

Timing Belts for the Food Sector (FDA)

In the food, pharmaceutical, and cosmetics sectors, conveyor system requirements often involve materials that differ from those typically used in standard solutions. To better meet market demands, we have expanded our range of belts that comply with FDA specifications. Specifically, products that have not yet been packaged and will come into contact with the timing belt must be transported using FDA-approved materials, such as certain types of polyurethane, rubber, and silicone.

Timing Belts in Food-Grade Polyurethane (FDA)

This product is characterized by the use of thermoplastic polyurethane that is FDA certified. Typically blue in color, it comes in varying hardness levels ranging from 60 to 90 Shore.

Timing Belts with FDA Coatings

FDA-approved coatings can be applied to the back of the belt using either cold gluing or hot-applied systems, ensuring compliance with certification standards.

Belts with Attachments and Machining in FDA-Approved Versions

Belts with cleats, as well as those with generic machining or designed for vacuum systems, can be produced with the same geometric characteristics as standard products, but using FDA-approved and certified materials.

Machining, Joints and Vacuum on Timing Belts

Our extensive experience enables us to provide any required machining on timing belts and their coatings, both solid and foam. Using CAD and CNC machinery, we can quickly design and produce custom geometries to meet drawing specifications. To ensure a high standard of quality, we employ specialized equipment for precise belt positioning and custom tooling.

Machining for Suction (Vacuum) Systems

In the automatic machinery sector, some applications require more grip than what the belt coating provides to transport products. In such cases, machining can be performed to convert the timing belt into a suction (vacuum) system.

Machining on Belt Coatings

Geometries that closely resemble the product being transported can be created on the back of the timing belt, allowing for precise placement within the compartment formed by the machining.

Mechanical Joints with Pins

In addition to welded joints, machining can also be done at the ends of the timing belt to create a mechanical joint. By drilling transverse holes in the teeth and inserting cylindrical pins, a highly reliable joint is formed, offering load capacities similar to traditional welded joints.