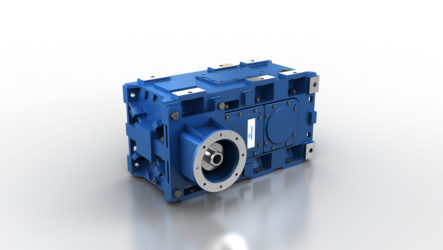

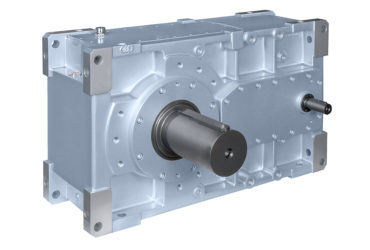

TECNICA INDUSTRIALE, during its 50 years of activity, has developed high technical skills in the complete repair and revamping of a wide range of gearboxes and gearmotors (planetary, right angle, worm screw, parallel axes gearboxes etc…)

The experience gained in the design of mechanical transmissions allows us to offer a gearbox rebuilding service intended for both plants manufacturers / technicians and end users. TECNICA INDUSTRIALE, in collaboration with the technical offices of the most important manufacturers of gear motors, designs and repairs every type of gearbox and mechanical transmission and provides tailor-made solutions for every need of its customers.